carton bursting strength test|paper burst strength chart : exporting The bursting strength of a corrugated sheet can be easily calculated by performing the bursting strength test or the Mullen test. This is . 13 de out. de 2023 · ACESSE A YOUCINE:🍿🎥 https://appp.fyi/jujuONDE ME ENCONTRAR?😄Redes sociais:🟪DISCORD: https://discord.gg/yzJMYjc4ZR ️INSTAGRAM DO .

{plog:ftitle_list}

webVivo no Flamboyant Shopping Center, receberinformação de compras: horários de funcionamento, localização de loja e ofertas e cupons de desconto. Vivo fica em .

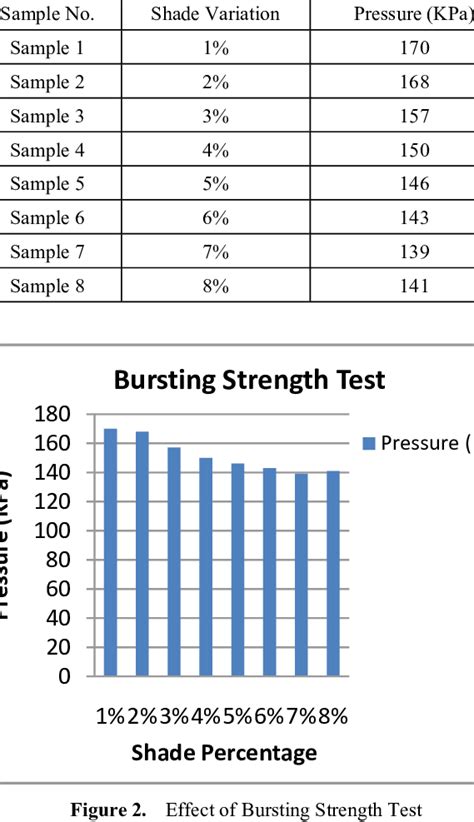

paper burst strength chart

When determining the strength of a box, the corrugated box industry uses two test, the Bursting (Mullen) Strength Test and the Edge Crush Test (ECT). The Bursting Test is reported in .Until 1991, the only method available for measuring the strength of corrugated was the Mullen Test, (also known as the Bursting Test). The Mullen Test, which is still used, is a good way to .

The bursting strength of a corrugated sheet can be easily calculated by performing the bursting strength test or the Mullen test. This is .

takemura soil ph & moisture meter dm15

A newer standard that has achieved widespread acceptance is the Edge Crush Test (ECT). This is a true performance test and is directly related to the stacking strength of a carton. ECT is a . Learn about the history of corrugated strength testing and the two standard test in the industry: the Mullen burst test, and the edge crush test or ECT. The bursting strength of a corrugated sheet can be easily calculated by performing the bursting strength test or the Mullen test. This is the most efficient testing procedure that is designed for testing the bursting . Testing Corrugated Strength: Mullen Burst Test versus Edge Crush Test . If you’ve ever received a shipment that arrived in a damaged box, then you know how important it can be to get box strength right. In fact, your .

a product during shipment. Bursting strength is reported in pounds (for example, A newer standard that has achieved widespread acceptance is the Edge Crush Test (ECT). This is a true performance test and is directly related to the stacking strength of a carton. ECT is a measure of the edgewise compressive strength of corrugated board.Board — Determination of bursting strength Carton — Détermination de la résistance ('11'éclatement Reference number ISO ISO 2014 t. Csetžahmad4 rozita Rosa", . the test piece ruptures. The bursting strength of the test piece is the maximum value of the applied hydraulic pressure, reserved ISO Na or pormdtgd IHS rozita MST .

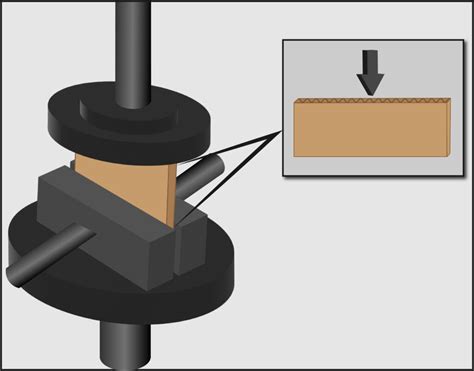

Digital bursting strength tester at best price in India. Get quotation from a top manufacturer and supplier of bursting strength tester / BS testing machine. . Test Standards: ASTM D 3786-01, ASTM D 3786 – 80A, ISO 1060 PART-1 1987. . carton box, card board, leather, cloth or synthetic leathers. We are happy that we chose Testronix .Key Point for Bursting Strength Test. It is important that the diaphragm area is divided by the hydraulic load to determine the bursting factor, which indicates the strength of the sample. This procedure is used to measure the bursting strength of paper, corrugated cardboard, carton box, card board, leather, cloth, or synthetic leather. This .

The burst test determines the maximum resistance (in kPa) of a specimen to an increasing pressure. ZwickRoell burst testers determine the bursting strength of paper in accordance with ISO 2758.The bursting strength of board and paper to ISO 2759 can also be determined with ZwickRoell, thereby covering the entire range from paper to heavy corrugated board.The burst test is frequently used as a general guide to the strength of paper, solid board and corrugated board. Bursting strength is usually quoted in kPa. We determine bursting strength using a digital hydraulic paper or digital hydraulic board burst tester as shown below. Burst index (kPa.m2/g) = burst strength/basis weight. #5 – Burst Strength is Key to Passing Drop Tests. In order to ensure that your cartons are strong enough to pass a drop test, burst strength is one of the main considerations to keep in mind. Burst strength is a measure of a box’s resistance to rupturing. It is measured in Pounds per Square Inch (PSI).Bursting strength is reported in pounds (for example, 275#). A newer standard that has achieved widespread acceptance is the Edge Crush Test (ECT). This is a true performance test and is directly related to the stacking strength of a carton. ECT is a measure of the edgewise compressive strength of corrugated board. It is measured by compressing .

Bursting strength is reported in pounds (for example, 275#). Edge Crush Testing . A newer standard that has achieved widespread acceptance is the Edge Crush Test (ECT). This is a true performance test and is directly related to the stacking strength of a carton. . On average, the 275# Burst Test rated single wall carton will weigh 175 pounds .ISO 2759:2014 specifies a method for measuring the bursting strength of board submitted to increasing hydraulic pressure. It is applicable to all types of board (including corrugated and solid fibreboard) having bursting strengths within the range 350 kPa to 5 500 kPa. It is also applicable to papers or boards having bursting strengths as low .

Corrugated cartons are primarily used as a secondary packaging medium and are also know as “Shippers” As in all types of packaging, its main purpose is to pr.

The ECT and Mullen Test both test box strength. The difference is the type of strength measured. Contact our experts to find a box that fits your needs. 800-261-7007. Corrugated Packaging. Corrugated Package Design; . Mullen Test (Burst Test) for Box Strength. The Mullen Test (burst test) has been used for over 130 years to determine how .

Bursting Strength berasal dari kata bahasa inggris yaitu ‘’burst’’ yang berarti meledak atau meletus dan “strength” yang berarti kekuatan. Istiliah Bursting Strength merujuk pada pengukuran kekuatan yang dibutuhkan untuk meledakkan atau meletuskan lembaran carton box atau corrugated sheet dalam horizontal hingga lembaran tersebut .TAPPI T 807, Bursting strength of linerboard, Test Method [6] TAPPI T 810, Bursting strength of corrugated board, Test Method [7] TAPPI T 1200, Interlaboratory evaluation of test methods to determine TAPPI repeatability and reproducibility [8] Brauns O., Danielsson E., Jordansson L., Svensk Paperstidning 23 867 (1954) 1) [9] After applied, ISO 2759:201 to find out the impact of different GSM on paper bursting strength test, impact of different types of paper on carton strength and impact of carton ply on carton strength test. First here applied .Corrugated boxes are becoming more significant in modern manufacturing. Bursting strength, as one of the most reliable indicators of corrugated carton quality, is impacted not only by the moulding process and printing design but also by environmental conditions.Thus, the manufacturers need to be extra cautious about the factors that can influence the strength and .

Bursting strength testers for cardboard & paper testing assesses that at what estimation of weight in kg/cm², the test gets break and burst out. Test methods for bursting strength testing instrument: JIS L 1004, L 1018 , L 1031, K 6328, P 8131 , P 8112, ASTM D2210, TAPPI T403 , ISO 2579-2014 GB/T1539.a product during shipment. Bursting strength is reported in pounds (for example, A newer standard that has achieved widespread acceptance is the Edge Crush Test (ECT). This is a true performance test and is directly related to the stacking strength of a carton. ECT is a measure of the edgewise compressive strength of corrugated board.Burst Strength Test hay Thử nghiệm độ bục Mullen – Kiểm tra độ bền chịu bục bao gồm đánh giá khả năng bảo vệ của tấm bìa carton, đặc biệt để ngăn ngừa các trường hợp xử lý không chính xác và thô bạo trong quá trình vận chuyển.

Edge Crush Test Vs Bursting Strength Test for Corrugated Boxes. The prime reason for the popularity of corrugated packings is its cost-effectiveness and light-weightiness. Despite being lightweight, it has very strong strength characteristics. A box manufacturer stamps the boxes with a certificate that describes the quality of the box.test. It is recommended to use the latter method. Further experimental studies involved the construction of rigs for testing corrugated board panels under compression and cylinders under combined stresses. The panel test rig, furnishing simply supported boundary conditions on all edges, was used to study the buckling behaviour of corrugated board.

To Calculate the Carton BF and BI, you first need to measure the burst strength of the packaging material. Once you get the burst value, using the below-mentioned calculation, BF and BI can be derived. . Presto Bursting Strength Tester is Universally acclaimed with Test Standards of ASTM D 3786-01, ASTM D 3786 – 80A, ISO 1060 PART-1 1987 .A test piece, placed over a circular elastic diaphragm, is rigidly clamped at the periphery but free to bulge with the diaphragm. Hydraulic fluid is pumped at a constant rate, bulging the diaphragm until the test piece ruptures. The bursting strength of the test piece is the maximum value of the applied hydraulic pressure.

Bursting strength is a traditional measure of paper strength and it is also a test requirement for corrugated board. Features: 1. Very fast testing cycle gives fast feedback to the production. 2. With automatic test grip instead manual hold the sample. 3. Improvement of the operational safety [email protected] +91 9313 140 140. Clients

takemura soil ph and moisture meter

WEB19 de out. de 2020 · Mudar de vida muitas vezes é necessário, mas isso pode trazer medo, inseguranças, incertezas. A maioria das pessoas se encontra em uma zona de .

carton bursting strength test|paper burst strength chart